Expanded Meses

General Characteristic

Figures 1 and 2 show the general geometry of Raised and Flattened mesh sheets.

The Raised sheets are the first step of manufacturing the product and through another process is converted to Flattened sheets.

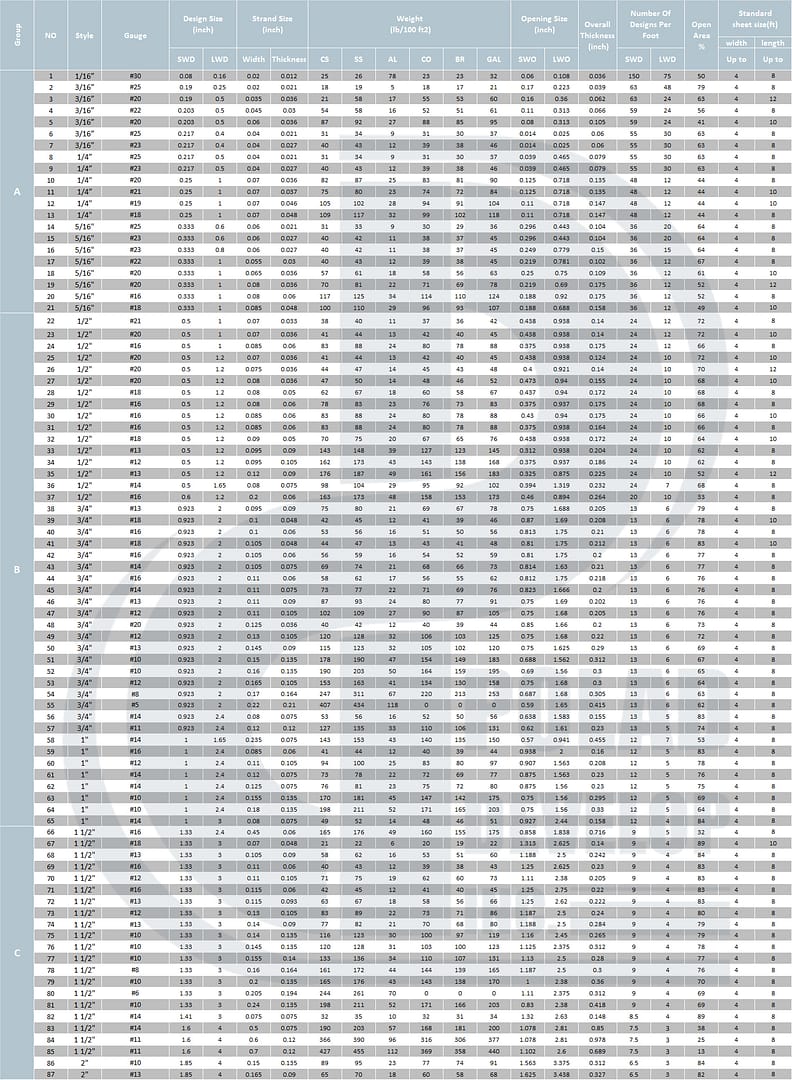

General geometric specifications for different metals can be seen in the table below

Definitions

Strand Width

The width of sides of mesh units or diamonds.

Strand Thickness

The thickness of sides of mesh units or diamonds.

This thickness is equal to the thickness of the raw material sheet.

Bond

The intersection of two strands is called the Bond. Its width is always double that of the strand width.

SWD

The axis – to – axis distance between two consecutive Bond which is measured across the longest side.

LWD

The axis – to – axis distance between two consecutive Bond which is measured across the longest side.

SWO

The inside-to-inside distance of two consecutive Bonds which is measured across the shortest side.

LWO

The inside-to-inside distance of two consecutive Bonds which is measured across the longest side.

Overall Thickness

The actual measurement of the thickness of the mesh measured at the Bond.

In Flattened mesh, the value of the overall thickness is equal to the strand thickness.

Open Area

The approximate percentage of the opening and extension of the mesh relative to the raw material sheet.

Gauge

A number which has been defined based on the thickness of standard metal sheets. Further details are shown in Raw Material SPEC .

Geometric Specifications of Common Expanded Metals

Abbreviations: CS=Carbon Steel, SS= Stainless Steel, Al= Aluminum, Co= Cooper, Br=Brass, Gal= Galvanized Steel

The values shown in table, presents internationally accepted common and may be different than North American values